Alibaba

Made in china

YouTube

Wechat/Whatsapp: +86 158 9501 0780 | EMAIL:info@iklaym.com

Do you want to make the most of biomass raw materials, especially waste biomass materials?

Biomass pellet plant has fully realized this idea by making wood pellets from various biomass materials. Wood pellets can be used as the fuel for civil heating& living energy, biomass industrial boiler, power generation and a base for mushrooms etc. Really turn waste to treasure.

Biomass pellet mill factory can process many materials, such as wood, sawdust, bagasse, coffee grounds, peanut shells, farm plants (stalk, straw, wheat stalk, bean stalk, cotton stalk, bean shells etc), grass, organic waste etc.

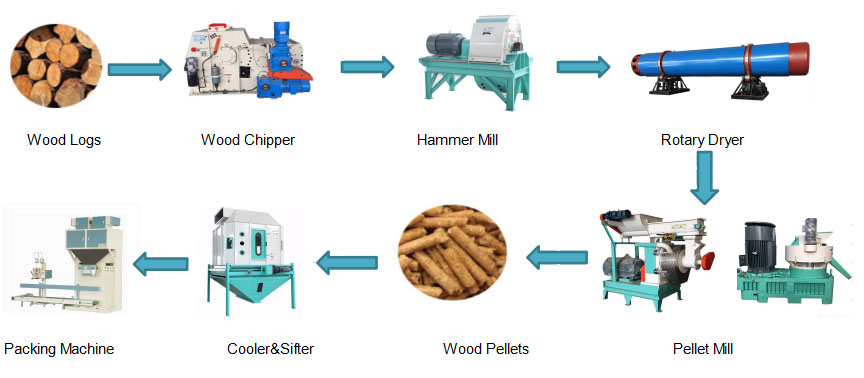

Chipping→Grinding→Drying→Pelletizing→Cooling &Sifting→ Packing Process (Take the wood as an example, different raw materials, the full flow chart will be a little different. More information, welcome to contact us info@iklaym.com.)

Simple Introduction for main machines:

| Wood Chipper: | Cutting wood, logs, tree limbs and trunks into <3mm thickness and 10-50 mm length wood chips. |

|---|---|

| Hammer Mill: | Crushing the material into small size (below 10mm) before pelletizing process. |

| Dryer: | In general, the moisture content of raw material is still high after grinding, which is not suitable for pelleting. The dryer can make moisture content from around 50% to 15%. |

| Pellet Mill: | Making wood pellets, it is the soul of complete biomass pellet plant. According to raw material and production needs of customers, choosing suitable pellet machine is very important. |

| Cooler& Sifter: | After pressed by the pellet machine,then cool wood pellets. And rotary screener or vibrating screener are used for sifting pellets. It is most commonly used in complete pellet plant. |

| Packing Machine: | It can weigh and pack the cooled pellets automatically. 10-50kg per bag is available to choose. |