Product Details

PELLET MILL DIES

We are a professional manufacturing factory for Ring Dies, Pellet Dies, Flat dies, Feed Mill Pellet Ring Dies, Pellet Mill Ring Dies, Animal Feed Pellet Mill Ring Die, Pellet Machine Ring die, Pellet Press Ring Die, Wood Pellet Machine Ring Die, ring die accessories etc. spare parts.

INTRODUCTION FOR PELLET MILL DIES

Ring dies/Flat dies are one of very important spare parts of pellet machines in the whole manufacturing process. The quality of pellet dies not only directly relates with the quality and output of feeds or pellets, but also the running state of equipment and maintenance cost.

1. Material of the ring die: X46Cr13 /4Cr13(stainless steel), 20MnCr5/20CrMnTi (alloy steel) or customized

2. Hardness of ring die: HRC54-60.

3. Diameter of ring die: 1.0mm up to 16mm

4. Pellet die type: Ring Die or Flat Die

5. Outer diameter: Outer diameter up to 1800mm

6. Pellet Die model we can customize:

OGM, Shenda, CPM, Buhler, CPP, OGM, Zhengchang(SZLH/MZLH), Amandus Kahl, Muyang(MUZL), Yulong(XGJ), AWILA,PTN, Andritz Sprout, Matador, Paladin, Sogem, Van Arssen, Yemmak, Promill& etc. We can customize any model according to your drawing.

PROCESS FOR PRODUCING PELLET DIES

Blank raw material Forging---Rough turning/lathing--- Drilling--- Countersinking--- Screw hole--- Keyway milling--- Heat treatment--- Fine turning/lathing--- Inspection&Package

Following are main process and our advantages:

Raw material of pellet mill die

1.The use of superb raw materials technology, less impurities, high purity, greatly reduce the content of harmful elements (such as elements S, P), thereby improving the comprehensive mechanical properties of the material.

2. Through CNC roller forging, the material is processed and strengthened, the material fiber is complete and uniform, and the comprehensive mechanical properties of the material are improved.

3. Using the world's advanced forging equipment and technology, electronic data processing system and perfect quality control system.

4. Strictly controls the hardness of the blanks, ranging from HB170 to HB220. If the hardness is too high, the drill bit is easily broken, and die holes will appear when drilling. If the hardness is too low, the surface finish of the die hole will be bad.

5. In order to control the uniformity of the material inside the blank, each blank must be tested for failure to avoid defects, no porosity, cracks and inclusions.

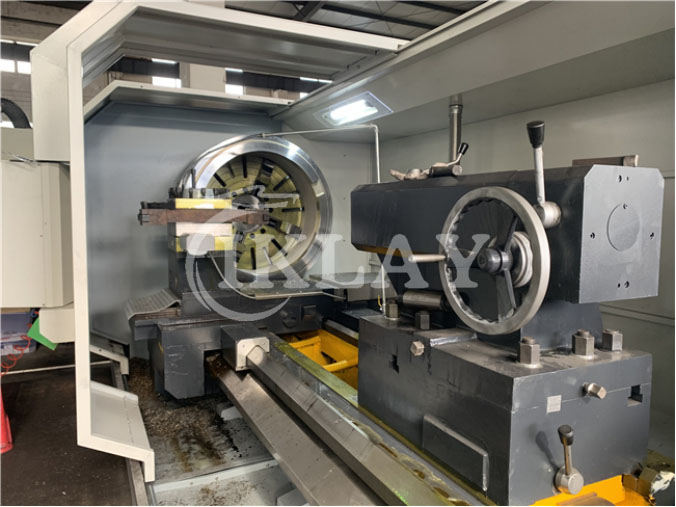

CNC Lathe machining

CNC automatic gun drill machine for drilling ring dies/matrices

1. It can process ring dies with various diameters and compression ratios above 1.0mm (including 1.0mm).

2. Ring die size can be processed to diameter (300mm-1500mm) * height 500mm.

3. All automatic control of ring die processing, one-time forming of die holes, high polished and good forming.

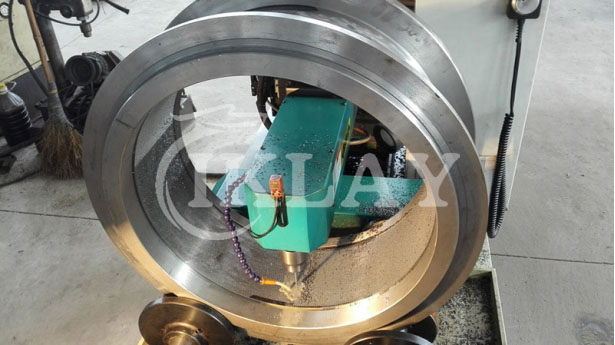

Automatic countersinking

All horn mouths are more smooth and uniform by automatic countersinking machine.

Horn mouths with special angle & depth, it can ensure longer service life and easier to make feeds/ pellets.

Heat treatment for pellet mill dies

1. Choose vacuum furnace and continuous quenching furnace, multi-purpose furnace processing technology to ensure long service life;

2. After processing and heat treatment, the hardness of the stainless steel ring die can reach HRC 52-58 (inner diameter less than 350mm), HRC50-56 (inner diameter greater than 350mm), which is more wear-resistant and corrosion-resistant. The hardness of alloy steel ring die can reach HRC57-60.

3. In order to control the hardness uniformity of the ring die after heat treatment, we select more than three points in each part of the circumferential direction to test the hardness and take the average value. The hardness value difference between each part should not be higher than HRC4

Inspection& Packaging

1.Raw material testing( Ultrasonic test)

2.Finishing at countersink and holes

3.Hardness test

4.Tolerance Check

5.Perpendicularity check for tapped holes

6.Outside relief depth and pattern of relief, compression ratio